What are the power and air supply requirements for an automatic film sticking machine?

Release date:2025.05.23

The automatic film sticking machine has clear technical requirements for power supply and gas source during operation, which directly affect the stability and work efficiency of the equipment. Understanding and meeting these requirements is of great significance for the normal use and maintenance of equipment.

Firstly, the power supply system of automatic film sticking machines generally adopts industrial electricity standards. The common power supply voltages are 220V single-phase and 380V three-phase. The specific voltage used depends on the power and design requirements of the equipment. Small or portable automatic film sticking machines often use 220V single-phase power supply, which is convenient for on-site use and installation; Industrial grade automatic film sticking machines with higher power usually require a 380V three-phase power supply to meet larger current loads and stable power output. The power frequency is usually 50Hz or 60Hz, which is consistent with the local power grid standards.

The rated power of the equipment varies greatly depending on the machine model and function, generally ranging from a few hundred watts to several kilowatts. The power supply system needs to have good voltage stability to avoid abnormal equipment operation or performance degradation caused by voltage fluctuations. When connecting the power supply, it is recommended to equip appropriate protective devices such as circuit breakers, leakage protectors, and voltage stabilizing equipment to ensure that the power supply quality meets the technical specifications of the equipment.

Secondly, the air source is an indispensable auxiliary power for many automatic film sticking machines, especially when using pneumatic systems to achieve film material transportation, positioning, and bonding actions. Automatic film sticking machines usually require a stable and moderately pressurized compressed air source to be connected. The common range of gas source pressure is generally between 0.4MPa and 0.8MPa, and the specific value is specified by the equipment manufacturer in the technical parameters. Low air pressure can cause insufficient cylinder movement, affecting the continuity of the film coating; If the air pressure is too high, it may accelerate the wear of pneumatic components and shorten the service life of the equipment.

The quality of the gas source also has a significant impact on the equipment, requiring a clean and dry gas supply system to avoid impurities and moisture from entering the gas path. It is usually recommended to install air filters, oil-water separators, and drying devices to ensure the purity and stability of the air source. The layout of the gas source pipeline should be reasonable to reduce airflow resistance and leakage, ensuring the operation of the pneumatic system of the equipment.

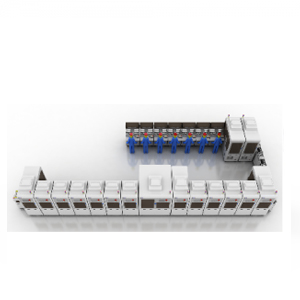

The pneumatic components of the automatic film sticking machine include cylinders, air valves, air pipes, and joints, all of which need to be well matched with the air supply system in order to achieve smooth mechanical action. The air circuit design usually adopts a modular approach, which is easy to maintain and replace. The specifications of the gas source interface should comply with the equipment design standards to ensure a tight and leak free connection.

In addition, the layout of power and gas supply systems should also take into account the overall installation environment of the equipment. The power supply line should comply with electrical specifications, with neat wiring and easy maintenance; The gas source pipeline should be securely fixed to prevent mechanical vibration and collision from affecting pipeline safety. For large automatic film sticking machines, a well-designed air and power inlet position can help reduce obstacles and failure rates during equipment operation.